Did You Know?… Life Cycle Assessment tools consistently show geosynthetics are the greener choice when it comes to construction

Life Cycle Assessment (LCA) is a key tool used to evaluate the environmental benefits of using different technologies or products during construction. It offers not only a basis for better economic decision-making but shows the ecological impact of choosing a particular method of construction.

So how does it work? LCA measures the environmental impact of products or systems over their lifetime. This includes the extraction of raw materials, production, use, recycling and disposal of waste. The method is often used to compare the impact of two competing products or systems, with the analysis process informed by ISO14040 (ISO 2006a) and ISO14044 (ISO 2006b) or other approved tools.

One of the most common measurements made by a LCA is calculating the Embodied Carbon (EC) of geosynthetic construction solutions. EC means all the carbon dioxide emitted in producing materials, from the construction process to disposal at the end of its lifetime. Outcomes show that incorporating geosynthetics in construction projects is consistently more sustainable than traditional construction materials based on EC and other environmental indicators.

Savings in EC are often realised because geosynthetics enable the use of ‘marginal’ soils – land that has little agricultural or industrial benefits – and which are often site-derived, thus reducing the amount of imported fill material. This minimises transport-related carbon emissions.

Beyond LCA

There is a growing body of evidence detailing the sustainability credentials of geosynthetic-based solutions. These invariably use a variation of the LCA approach, and all include comparisons with non-geosynthetic solutions. The amount of savings differs from application to application, but all LCAs to-date have shown that the use of geosynthetics results in the reduction of environmental impacts.

These studies include:

- WRAP – case studies from the UK-based climate action group, which works in more than 40 countries to tackle the causes of the climate crisis, showed how the use of geosynthetics, amongst other benefits, could reduce the amount of imported fill. This provided CO2 savings from EC emissions from the quarrying of fresh fill, and also eliminating the need to transport these materials on and off site. The study (2010) concluded that construction solutions incorporating geosynthetics led to significant cost and CO2 savings for reinforcement applications.

- European Association of Geosynthetic Manufacturers (EAGM) – considering four construction systems against eight environmental impact indicators, the EAGM-commissioned study found geosynthetic-based solutions were consistently assessed as more sustainable compared to the performance of traditional construction materials.

The construction systems considered were filtration, foundation stabilization, a landfill drainage layer, and a soil retaining wall. The alternatives in each case were defined such that they can be considered technically equivalent or at least comparable. The eight environmental impact indicators were cumulative energy demand, climate change (global warming potential, GWP100, carbon footprint), photochemical ozone formation, particulate formation, acidification, eutrophication, land competition, and abiotic resource depletion (excluding fossil fuels).

Several studies also concluded that geosynthetic-based solutions delivered significant cost savings. The methods outlined can be used to undertake site-specific calculations that inform decisions on a selection of construction approaches that contribute to sustainable practice.

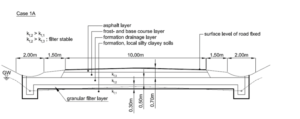

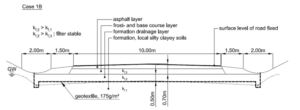

One example of the benefits is in the case of filter layers. Geosynthetics are used in soil engineering, where they can serve as a filter medium. The cross-section diagram here shows a mineral filter system (Case 1A) compared to a filter using geosynthetics (Case 1B).

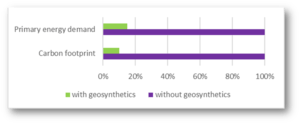

As shown in the figure below, the energy demand and carbon footprint in Case 1B is significantly lower than in Case 1A.

Summary

Across the board, LCAs consistently demonstrate the environmental and cost benefits of using geosynthetic solutions in construction over other methods. These include:

- Minimizing CO2 and preventing further emissions

- Saving natural resources

- Reducing the energy demand (CED, or cumulative energy demand)

- Saving fresh water

- Reducing construction costs

Clearly, geosynthetics are a key part of the solution when it comes to making cost savings and a positive environmental impact before, during and after construction projects.

Geosynthetic solutions should be fully investigated on every infrastructure project to ensure they meet the needs of the present without compromising the ability of future generations to meet their own needs.

Find out more about how geosynthetics are making a difference by downloading the IGS Sustainability eBook here or visiting our Sustainability page.